Mark Lombard

Director, Division of Spent Fuel Management

You may have heard that the NRC has received an application today for a centralized storage facility for spent nuclear fuel. We thought this would be a good time to talk about what that facility would do, and how we will review the application.

First some background. “Spent fuel” is the term we use for nuclear fuel that has been burned in a reactor. When spent fuel is removed from a reactor, it is very hot, so it is put immediately into an onsite pool of water for cooling. Initially, the plan in the ‘70s had been to send the spent fuel for “reprocessing” prior to final disposal, so usable elements could be removed and made into fresh fuel. But reprocessing fell out of favor in the United States in the ‘80s.

To manage their growing inventory, nuclear utilities turned to dry storage. The idea behind dry storage casks is to cool the fuel passively, without the need for water, pumps or fans. The first U.S. dry storage system was loaded in 1986. In the past 30 years, dry storage has proven to be safe and effective.

Against this backdrop, a Texas company, Waste Control Specialists (WCS), filed an application with us today for a dry cask storage facility to be located in Andrews County. WCS plans to store spent fuel from commercial reactors; initially, from reactors that have permanently shut down.

The application discusses utilizing dry storage casks that have previously been approved by the NRC. The spent fuel would arrive already sealed in canisters, so the handling would be limited to moving the canisters from transportation to storage casks.

Ever since Congress enacted the first law for managing spent nuclear fuel in 1982, federal policy has included some centralized site to store spent fuel before final disposal in a repository. Congress made DOE responsible for taking spent fuel from commercial reactors. It gave NRC the responsibility to review the technical aspects of storage facility designs to ensure they protect public health and safety and the environment.

We conduct two parallel reviews – one of the safety and security aspects, the other of potential environment impacts.

But before those reviews get underway, we will review the application to see if it contains enough information that is of high enough quality to allow us to do the detailed reviews. If it doesn’t, WCS will have a chance to supplement it. If we find the application is sufficient and accept it, we will publish a notice in the Federal Register. This notice will alert the public that we have accepted the application for technical review, and offer an opportunity to ask for a hearing.

Then we begin our reviews. At the beginning of our safety and security review, NRC staff will hold a public meeting near the site to answer questions about our process. We’ll also have public meetings with WCS as needed so the staff can ask questions about the application. We will document this review in a Safety Evaluation Report.

Once we get public and stakeholder input on the scope of our environmental review, we will conduct the review and document the results in a draft Environmental Impact Statement (EIS). We’ll ask the public and stakeholders to comment on the draft. After considering those comments, we’ll finalize it.

We expect the review process to take us about three years, assuming WCS provides us with good information in a timely way during our review.

If interested parties ask for a hearing, and their petition is granted by our Atomic Safety and Licensing Board, then the board will consider specific “contentions,” or challenges to our reviews of the safety, security or environmental aspects of the proposed facility. The board will hold a hearing on any contentions that cannot be resolved. We can’t predict how long this hearing process would take.

The Safety Evaluation Report, the EIS and the hearing need to be complete before the NRC staff can make a licensing decision. If the application meets our regulations, we’re legally bound to issue a license. We don’t consider whether there’s a need for the facility or whether we think it’s a good idea. Our reviews look at the regulatory requirements, which are carefully designed to ensure public health and safety will be protected, and at the potential environmental impacts and applicant’s plans for mitigating them.

Incidentally, we are expecting an application for a second centralized interim storage facility Nov. 30. This one, to be filed by Holtec International, will be for a site in New Mexico. We’ll follow the same process in reviewing that application.

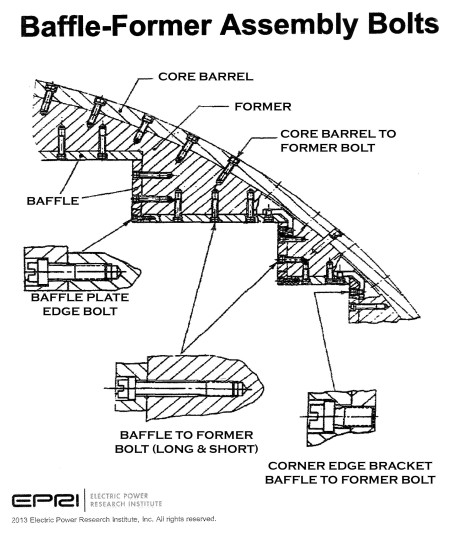

Specialists were geared up to check on the condition of bolts employed in the reactor vessel at the Buchanan, N.Y., facility. These are the kind of bolts you likely wouldn’t find at your local hardware store. Rather, they are made of a stainless-steel alloy capable of withstanding decades’ worth of neutron bombardment, as well as extraordinarily high temperatures and pressure.

Specialists were geared up to check on the condition of bolts employed in the reactor vessel at the Buchanan, N.Y., facility. These are the kind of bolts you likely wouldn’t find at your local hardware store. Rather, they are made of a stainless-steel alloy capable of withstanding decades’ worth of neutron bombardment, as well as extraordinarily high temperatures and pressure.